|

|

|

||

| Pneumaflex KA | Spiroflex KSS/KSP | Pneumastar KU | ||

|

Highly Elastic Cluthes

for torque of up to 304 kNm

Pneumatically switchable

.

The special qualities of a highly torsionally elastic and vibration dampening coupling and those of a pneumatically operated double cone friction clutch are purposefully combined in this PNEUMAFLEX clutch. It reliably interrupts or establishes the flow of power between the diesel engine and the other driving components. |

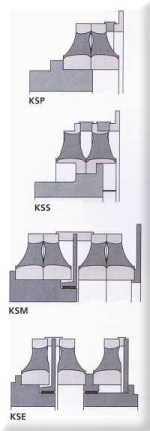

Highly Elastic Couplings

for torque of up to 928 kNm

Couplings for torques of 185 kNm and higher are equipped with segmented elastomer elements.

The highly torsionally elastic SPIROFLEX shaft coupling compensates, by virtue of its elastic rubber elements, radial axial and angular alignment deviations. Its high torsional elasticity and excellent dampening capability renders this coupling indispensable for propulsion systems prone to torsional vibration. |

Torsionally Stiff Clutches

Pneumatically switchable. For stiff, but switchable connections.

The PNEUMASTAR clutch is a torsionally stiff double-cone friction clutch. The clutching components consist of two inner and two outer friction cones of which the inner ones are pneumatically pressed against the outer tapered friction faces via a clutching cylinder operated pneumatically. Rubber sleeve springs form the torsionally stiff portion of the clutch. |